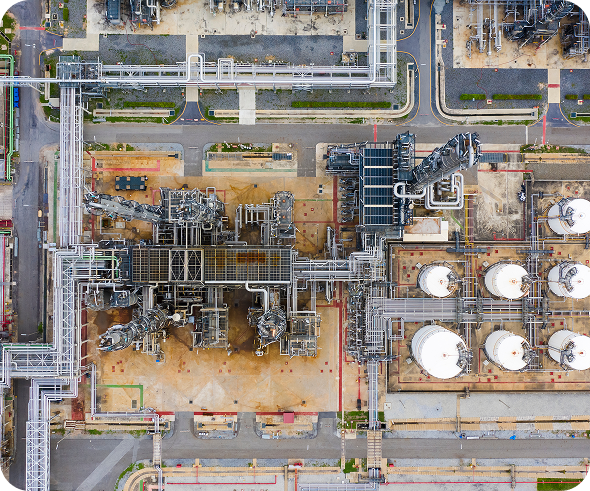

Manufacturing Industries

Embrace Industry with Kaizen Next Gen

In today’s industrial landscape, achieving operational excellence demands more than just modern equipment it requires connectivity, agility, and intelligence. At Kaizen NextGen, we empower manufacturing organizations to transform traditional factories into smart, data-driven operations. With our expertise in ERP, digital transformation, and Microsoft Dynamics 365, we enable faster production, seamless system integration, enhanced quality control, and sustainable growth.

Integrated and Automated Processes for Maximum Efficiency

Manual processes often lead to inefficiencies, inconsistent output, and elevated costs. Our manufacturing solutions streamline operations by integrating Dynamics 365 systems with existing line of business applications and third-party platforms. This end to end automation from production planning to real time monitoring boosts productivity and eliminates bottlenecks across every stage of the manufacturing cycle.

Key Outcomes

- Faster production cycles through reduced manual intervention.

- Automated alerts and notifications for critical process events.

- Seamless data flow and consistency across systems and teams.

Productivity Enhancement through Smart Resource Scheduling

Optimizing resources whether its inventory, labor, or machinery is central to reducing waste and improving throughput. By leveraging real time visibility and intelligent scheduling powered by Dynamics 365, Kaizen helps clients optimize production planning and dynamically allocate resources.

Key Outcomes

- Maximized utilization of materials and equipment.

- Accurate production forecasts and efficient shift planning.

- Reduced downtime and resource conflicts.

Inventory Optimization & Predictive Demand Planning

Avoid the twin pitfalls of stock outs and excess inventory with modern demand forecasting and inventory control. Our intelligent systems analyze historical data and trends to automate reordering, predict future production needs, and align procurement with actual business demand.

Key Outcomes

- Lowered inventory holding costs

- Fewer stock outs, ensuring smoother operations.

- Lean supply chain management with data-backed insights.

End to End Supply Chain Transparency

In a distributed manufacturing environment, real time visibility across the supply chain is essential. Kaizen NexGen empowers clients with full traceability from raw materials to finished goods while monitoring supplier performance and logistics. Our tools provide insights into defect rates, delivery timelines, and compliance metrics.

Key Outcomes

- Improved supplier collaboration and accountability.

- Faster issue identification and mitigation.

- Enhanced compliance through traceable processes.

Data Driven Insights & Predictive Maintenance

Unplanned downtime can cripple productivity. To combat this, we embed sensors and leverage real-time data analytics to facilitate predictive maintenance, ensuring machines are serviced proactively before failures occur. This strategy not only maintains high uptime but also extends the lifespan of critical equipment.

Key Outcomes

- Lower maintenance costs and equipment wear.

- High operational reliability with reduced unexpected breakdowns.

- Actionable dashboards for real-time decision-making.

Why Kaizen NextGen Leads in Manufacturing Solutions

1. Trusted Expertise

Decades of combined experience implementing Dynamics 365 in manufacturing environments fine tuned for discrete, process, and lean models alike.

2. Global Perspective, Local Execution

We bring international best practices while respecting local workflows and compliance needs.

3. Idiosyncratic Intelligence

Selective use of AI and automation helps you excel not just keep pace with your competitors.

Real-World Impact: Client Stories

1. Operational Uplift

A mid-sized electronics firm reduced production errors by 25% after implementing integrated planning and IoT-monitoring.

2. Inventory Revolution

A consumer goods manufacturer slashed carrying costs by 15% using automated replenishment powered by real-time inventory analysis.

3. Maintenance Resilience

A heavy equipment producer eliminated 30% of unplanned downtime with AI-powered predictive maintenance tools

Connect With Us to Explore